SOLUTIONS.

Stress less & get control

of your whole warehouse operation.

Welcome To Your NextWMS

You are in the right place if you need solutions for logistics and warehousing automation to increase efficiency and get control fast.

NextWMS is a flexible solution for most industries.

Key Features that will set you apart

Multi-Warehouse & Multi-Stock Owner Configuration

Manage complex business requirements and 3PL operations with NextWMS. You can easily tailor the way you work in each warehouse for each stock owner or 3PL client.

Continuous Improvement

All warehouse movements are tracked by activity and by user, so you have the data you need to identify process and productivity improvements.

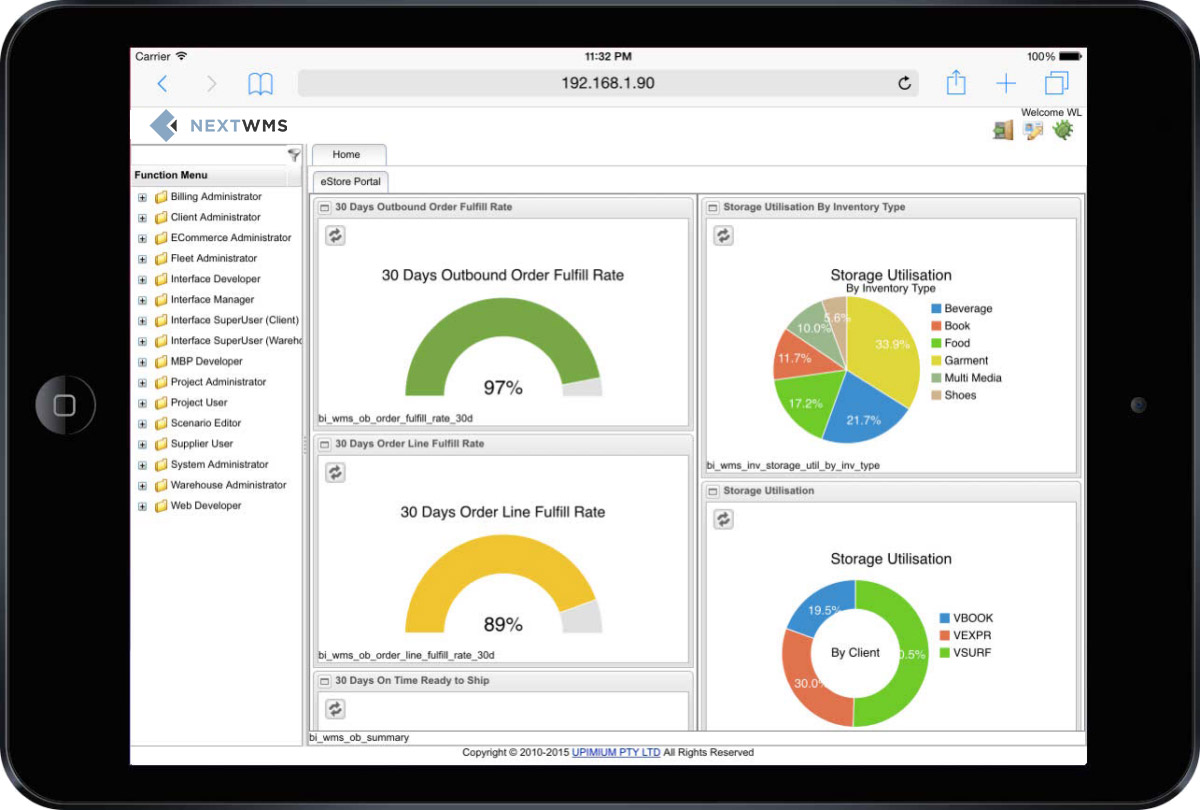

Realtime Transaction Visibility

Track all of your warehouse operations in real-time so you make sure everything runs smoothly and your customers are satisfied.

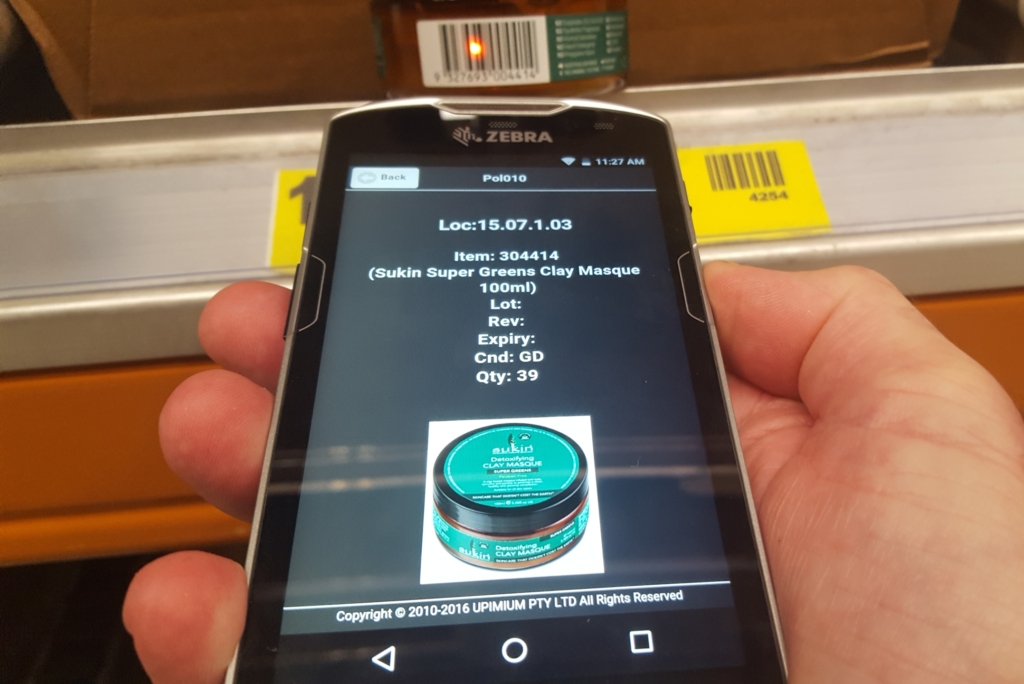

Easy to Use

Your staff will easily learn the natural and efficient mobile workflow. Barcode scanning eliminates errors and helps them get it right the first time.

Any Mobile Device

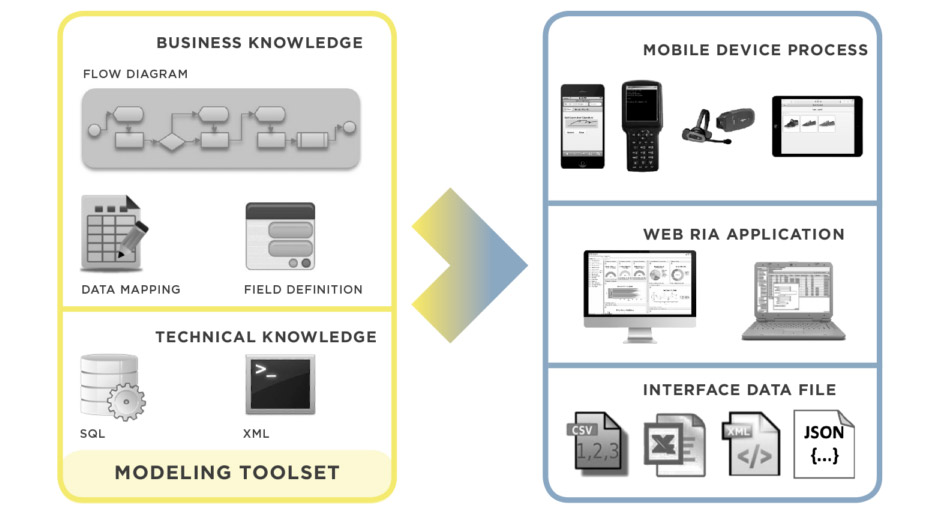

Traditional WMS requires a separate development for each type of mobile device due to the different technologies and screen sizes. Our “Write Once Run Everywhere” development platform can enable the same flowchart driven mobile workflow on any device, so that you can follow the same picking workflow whether your using desktop browser, smartphone, tablet, Voice device, or text-based RF gun

Agile Design Toolset

Our Agile design toolset empowers business analyst’s ability to quickly create or modify existing mobile workflow, web report and data integration with other systems without engaging a hard-core techie. This reduces implementation cost, and the cost of keeping your system up to date with your changing business needs.

Other Key Features

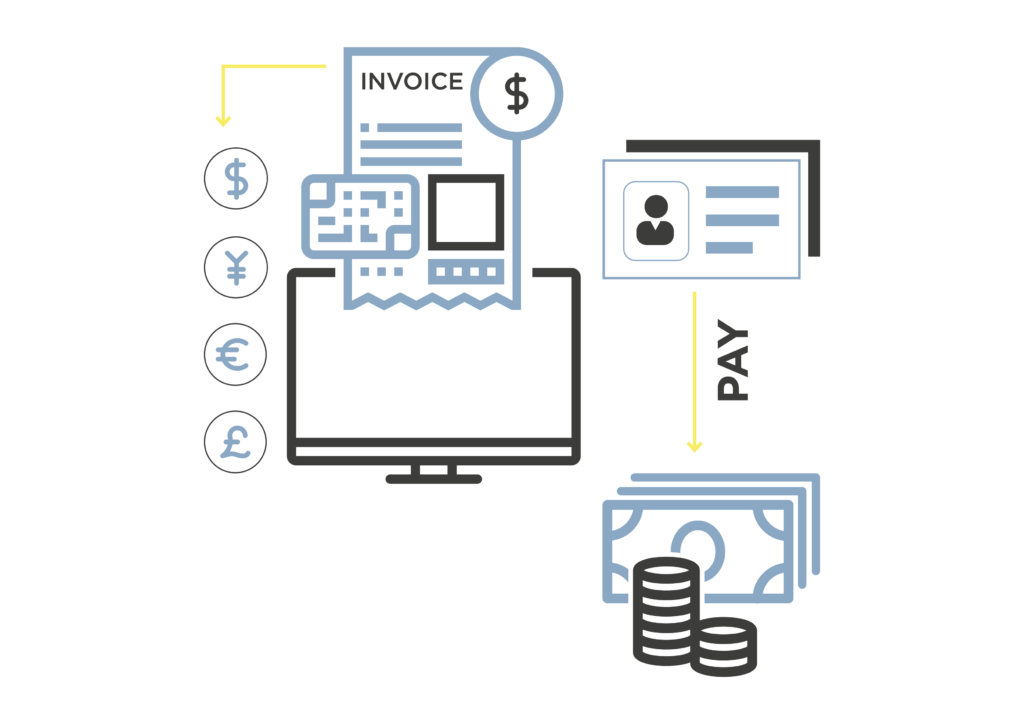

3PL Billing Management

- Set-up Rate Card by activity and transaction characteristics such as order type, item category, warehouse zone, location types

- Ability to generate billing transaction on daily basis

- Support weekly, fortnightly, monthly billing period

- Create ad-hoc manual billing transaction

- Generate an E-mail billing report

- Export billing transaction to other systems.

Value Added Services

- Manual set-up or import task instruction, material requirement and execution step detail.

- Generate preparation tasks to retrieve stock or print label for task execution

- Perform VAS task and log labour activity in real-time via mobile App

- Adjust stock automatically to reflect VAS task execution

Functionality Benefits

Receipt by mobile barcode scanning, paper-based processing and manual confirmation, or data interface from other systems

Schedule container docking, unload container pallets using mobile app and take photos for inspection

Receive stock by specific transaction type such as ASN, PO and RMA, with option to over receipt and receive unknown stock

Receive stock without referencing to any specific transaction type

Determine received stock condition by pre-defined criteria and script-based inspection steps, isolate stock by condition

Take photo of damaged product when received or during inspection and attach photo to transaction for inquiry

Prompt operator to capture missing information such as dimension and weight during receiving

Print receiving label in real-time or apply value added service for re-packaging or printing other item labels

Pick, Pack, Load and Ship by mobile barcode scanning, paper-based processing and manual confirmation, or data interface from other systems

Schedule automatic pick wave creation by configurable outbound order grouping profile

Manually assign outbound orders by ad-hoc criteria to pick wave or container load

Apply configurable stock allocation strategy such as FIFO, FEFO, efficient pick or pick to clean etc. to determine pick slot

Pick discrete order, or batch multiple and sort picks to each order tote in a single pick path for greater efficiency

Concurrently pick same order from multiple zones by different operators, or finish picking in one zone before passing to the next one

Breakdown order quantity to loose, carton and pallet unit of measure, pick full carton quantity with pre-printed pick labels

Pick multiple batches of order at once, sort picks to each batch tote in a single pick path for greater throughput during outsorting/put to wall

Outsort batch picked stock to designated wall slot or pallet location for each order in the batch

Scan and validate picked item into one or multiple shipping cartons and generate carton content & shipping label

Re-shuffle content in the cartons for optimal packing space utilisation

Unpack packed carton, Unpick picked items to make stock available for other urgent orders, or when order is amended

Bundle cartons going to same destination to same pallet, load pallets to container by the load plan

Ship order or orders in the load, generate shipping documents and confirmation message to other systems

Print pick label, shipping label, pick slip, packing list and shipping invoice in real-time as order progresses through each milestone

Hold, release, amend or cancel unprocessed order in real-time using Web API

Real-time integration with AS/RS, conveyor, pick to light, CAPS, camera and weighing scale

Real-time integration with IFS, Shippit, Starshipit and Yojee

Monitor and query real-time outbound order picking, packing, loading and shipping progress

Generate acknowledgment and confirmation message when outbound order progressing through each milestone in lifecycle

Check stock on hand by bin location, license plate, item and stock attributes

Adjust stock quantity in bin location or transfer to other attributes or owner and generate message to other systems in real-time

Scrap stock or change condition of the stock in bin location at once and generate message to other systems in real-time

Apply or release hold on stock in bin location or by specific stock attribute and generate message to other systems in real-time

Bundle carton licence plates to pallet master licence plate to streamline movement in the warehouse

Create inventory & move task to direct operator, reshuffle stock for pick efficiency

Apply various logics in selecting optimal location to putaway stock to consolidate by item, stock attribute, zone or else

Generate pick location replenishment tasks by min-max setup, outstanding demand or simply top up

Count stock quantity in location, lodge count discrepancy as adjustment

Generate stocktake task, count stock quantity and lodge variance to a pool for recount, finalise the net variance as adjustment

Query inventory movement in, out and within warehouse by item, bin location, licence plate, stock attributes or order number

Generate adjustment message in real-time, process and book stock movement transactions from MHE or other system